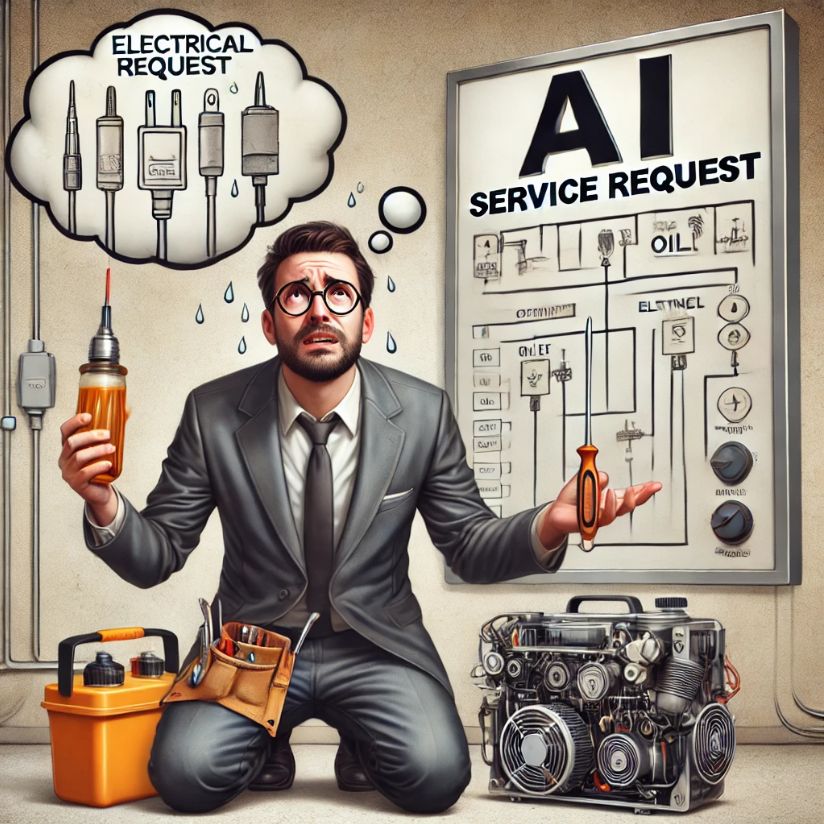

The Dark Side of Maintenance Management Software:

Why High-Tech Solutions May Not Be the Answer

As technology continues to advance, the use of software, IoT devices, and analytics in maintenance management has become more prevalent. While these tools promise to streamline maintenance processes, reduce downtime, and increase productivity, there is a dark side to relying too heavily on technology.

One issue with high-tech solutions is that they can be time-consuming and complicated to set up, requiring significant effort from busy maintenance staff. Additionally, software glitches and device malfunctions can cause further disruptions to an already busy workday, ultimately reducing efficiency and productivity.

Another problem with high-tech solutions is that they may not always provide the most effective solution. While analytics and data can help identify trends and patterns, they do not necessarily provide insight into the root cause of maintenance issues. Furthermore, these tools can lead to a lack of hands-on involvement from maintenance staff, resulting in a decreased understanding of the equipment and processes they are responsible for.

Finally, high-tech solutions can be expensive, making it difficult for smaller companies to afford them. This can create an uneven playing field where larger companies with deeper pockets have an advantage over smaller competitors.

In conclusion, while software, IoT devices, and analytics can offer benefits in maintenance management, it’s important to recognize that they are not a silver bullet. High-tech solutions require significant effort to set up and maintain, can lead to a lack of hands-on involvement, and may not always provide the most effective solution. As such, it’s important to approach technology with a critical eye and balance it with the expertise of skilled maintenance workers and managers.