Is Industry 4.0 going to eliminate maintenance?

Cassandra, the daughter of Trojan king Priam, possessed the gift of prophecy. However, her prophecies were often ignored, and the Trojans failed to act on the warnings she provided. They were aware of the high risks of war with the Greeks, and even received specific alerts about the danger posed by the Trojan horse, yet they did nothing. This begs the question: were the Trojans poor managers, or just had too many alerts to handle, and lack the resources to respond effectively? Could improved prediction tools, such as Cassandra 4.0, have helped them achieve better results?

Industry 4.0 is a common term for robots, sensors, and data analytics applications in production. In the field of maintenance, it is mainly focused on controllers, IoT sensors, their connectivity, and analytics. The vision of Industry 4.0 maintenance is 100% of tools connected and analyzed in the real time for early failure recognition. Most failures should be recognized by vibration, noise, electrical current and other measurements, before the failure occurs and causes to stop production.

But which pictures do maintenance professionals have in mind, when hearing about “the new brave world”? Is successful implementation of previous industrial revolutions (2nd was work standardization and 3rd – industrial controllers) has reduced the level of the technical skills required to keep the lines running? Has it changed the production to fully automatic lines, without need for highly skilled maintenance teams, that able to solve complicated technical issues on the fly?

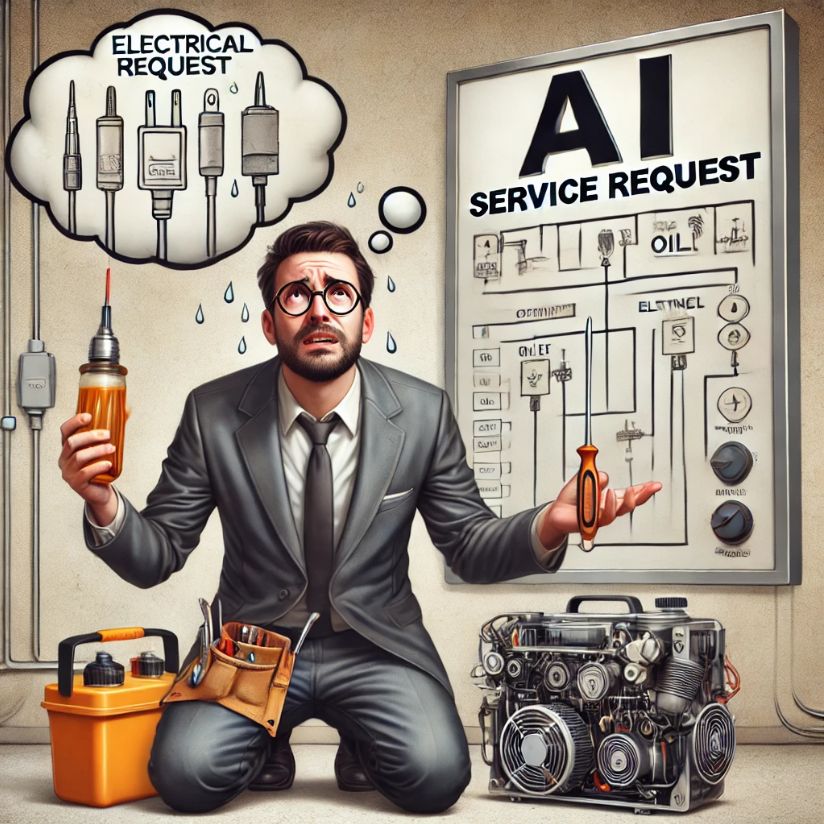

I think the picture is different. Failure prediction cannot replace part or repair the tool. In some cases, predictive maintenance looks remarkably like the old (and not good) run-to-failure, just the failure is recognized earlier. The rust stays rust, camera may recognize it faster than visual inspection by human, but removal still needs to be done. Alongside faster failure detection, the quantity of requests for failure repair will grow. If the plant does not have a strong maintenance team, the prediction will work in “Cassandra” mode, rising alerts without an ability to fix them on time.

No doubt, Industry 4.0 is a revolution, and data leads the way for improvement. But managers must keep in mind that someone needs to hold the wrench and to do the work on the ground.

#maintenance #production #anymaint #industry40